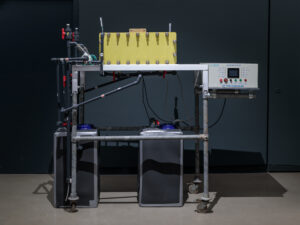

After 150 years of concrete construction development, 3D concrete printing now makes it possible to use the material precisely and, above all, economically. For the first time, filigree concrete elements can be produced quickly and without costly formwork construction. Lightweight ceilings made with the highly innovative digital process need 35 % less material than conventional in-situ concrete ceilings, which are usually the same thickness at all points. Now optimised concrete structures are printed as lost formwork and, where statically required, in-situ concrete is added. The scientific groundwork was carried out from 2015 to 2019 in the research project COEBRO – Additive Fabrication of Concrete Elements by Robots. The process is now being gradually further developed. If we consider the millions of ceiling elements concreted every year, this shows the enormous potential of the technology for saving resources and for a paradigm shift in concrete construction.

3D-printed Reinforced Concrete, 2021

Institute of Structural Design/Graz University of Technology (Georg Hansemann, Robert Schmid, Christoph Holzinger, Joshua Paul Tapley, Stefan Peters, Andreas Trummer)

Bildunterschrift

Project partners: Laboratory for Structural Engineering/Graz University of Technology, Baumit GmbH

With thanks to AVI GmbH, Doka Österreich GmbH, Leitner Unternehmensgruppe, Leviat, PRUACRETE.